Improving Your Precipitator Operation

Improvement or optimization of precipitator operation can result in significant savings. Many specific situations encourage a review of precipitator operation:

- Deterioration of existing equipment

- Tightening of air pollution emission regulations

- Changes in products and/or production rates

- Frequent forced outages

- De-rating of production

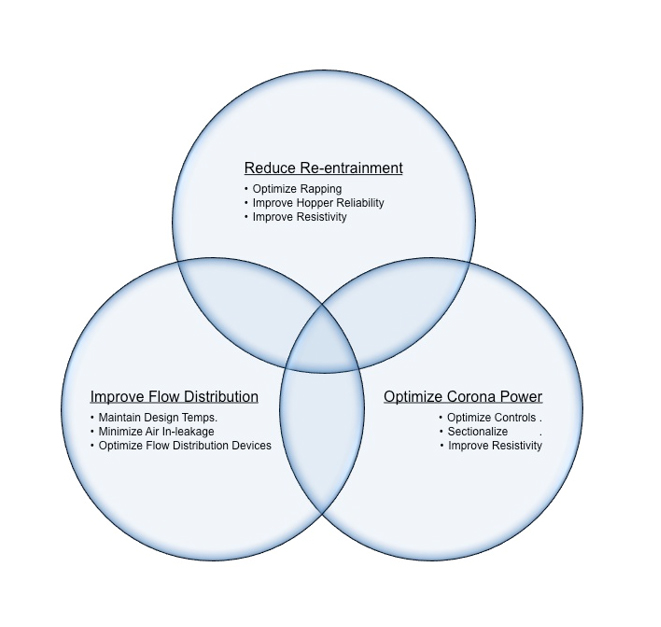

The key areas for performance improvement are reducing re-entrainment, improving gas flow distribution, and optimizing corona power.

Helpful Resources:

KnowledgeBase: Reduce ReEntrainment

KnowledgeBase: Optimize Corona Power

KnowledgeBase: Improve Gas Flow Distribution

Our Capabilities: Asset Lifecycle Management

OurCapabilities: Predictive Modeling