Best Practices for Electrostatic Precipitator Inspections

An effective electrostatic precipitator inspection is part of routine equipment maintenance. For example, at the municipal utilities power station in Sikeston, Missouri, precipitator blast-cleaning is done every year along with a walk-through and routine rapper tune-ups. Complete detail inspections and larger repairs are scheduled every other year during longer outages.

“By keeping up with this maintenance, and also doing a more thorough inspection every other year, we get a lot more longevity out of the run,” explains Ed Boyd, Sikeston’s electrical supervisor and project engineer, who has been in the industry for 34 years.

Any inspection, whether a quick walk-through or a more lengthy check-up, requires some legwork up front, and a plan for prioritization during and afterward. This article outlines best practices for a smooth inspection. If you’re doing the inspection yourself, treat this as a checklist. If you’re hiring a contractor, make sure these steps are part of their routine procedure.

First, clarify desired outcomes of the inspection with whoever will get a report afterward and is authorized to act on recommendations. Having a clear objective up front will save time, money and headaches later. The scope of work for a preventative maintenance (PM) inspection will be different from one focused on troubleshooting specific problems.

Next, get background information from people responsible for operating each area of the equipment (electrical, mechanical, ash handling). Ask these people if there are specific issues they’re troubleshooting. Piecing this information together will provide a picture of current operating conditions and possible problem areas. For example, electrical issues might be traceable back to hopper pluggage.

“It’s easy to get sidetracked or impatient looking for people who have this information,” notes Jim Parsons, Senior Environmental Consultant at Neundorfer, who has been doing inspections for 30 years. “But it’s worth spending the time gathering background information and clarifying expectations before jumping in the ESP box.”

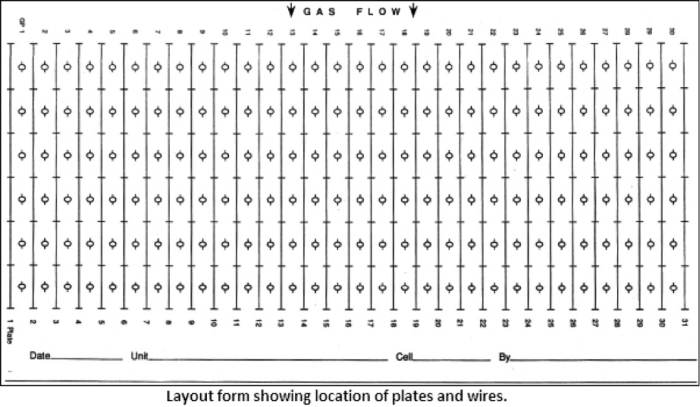

Background information gathered ahead of the inspection should include original design specifications. These specs enable you to create an accurate precipitator layout form (a grid showing the location of plates, wires and other components) to mark with notes during the inspection. A layout form is especially vital if you’re inspecting a large precipitator; without a map showing where things are located, the job can be daunting.

“After a while, it’s like walking around in a cave with sunglasses on,” Parsons says. “You can easily get overwhelmed if you don’t have a clear idea of what to look for.”

With design specs, information about troubleshooting efforts, and understanding about expectations, you can effectively prioritize where to begin and what to look for during the inspection.

Before actually heading into the precipitator, of course, make sure all safety protocols–including tag-out and lock-out–are being followed. This is high-voltage equipment and not something to mess around with.

Usually, the inspection scope of work includes a standard list of maintenance items and at least a few requests to look for specific problems. At Sikeston, inspection work is prioritized first based on job tickets, such as a report of rappers not operating properly. It’s also standard practice to check for broken insulators.

“We start with anything that’s obvious from the outside,” Boyd explains. “Then, we go inside and look for anything unusual.”

Things can get pretty interesting during an inspection if you are troubleshooting specific issues, but even a routine maintenance walk-through will turn up items in one area that impact performance elsewhere and require further investigation.

“If an ash line is clogged and we find foreign material when clearing it, during the inspection we go look for where that material came from,” Boyd notes, citing one troubleshooting example. “Or, if we do a quick inspection of the high voltage area and find arcing, we know there is moisture and we need to look for leaks.”

Finally, an exit review meeting should be part of any inspection. During this meeting, give the person you’re reporting to a punch list of items that need to be addressed right away.

A punch list is different from the more detailed report you’ll submit later, which will focus on longer-term follow-up. For example, if you find bowed plates in a section of the precipitator, the punch list might recommend pulling wires in those areas to prevent electrical shorts. The longer report would specify that the plates need to be straightened or replaced.

It’s important that any inspection be performed by experienced professionals who understand how all components of the system work, know what to look for, and are informed about how to prioritize what needs maintenance immediately and what can wait.

Helpful Resources

KnowledgeBase: Introduction to ESP

Our Capabilities: Performance-Based Maintenance

Our Capabilities: Equipment Assessments & Inspections

Our Capabilities: Outage & Project Management