Introduction to Baghouse / Fabric Filters: Bag Media

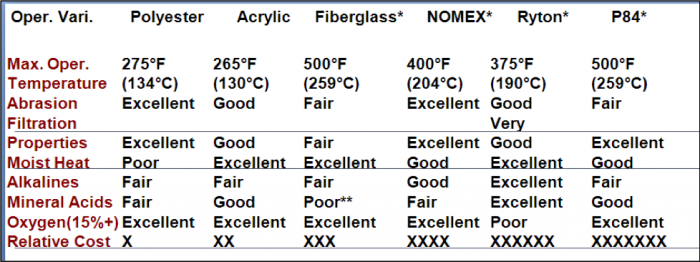

There are increasing options for filter bag media. Bag life varies by media type, cleaning energy and frequency, and changes to the gas stream. There is no best media, instead it needs to be selected for the application and bag life desired. These and other factors need to be taken into consideration when selecting bag media:

- Operating temperatures

- Abrasion resistance needed for the dust being collected

- Compatibility with air stream and gas

- Resistance to cleaning energy

- Gas stream chemistry

- Air-to-Cloth ratio

- Cleaning method

- Financial considerations

Another option may be pleated elements which may help undersized pulse jet baghouses perform better.

The table below provides limited information in regards to some potential bag media:

Helpful Resources

KnowledgeBase: Guidelines for Fabric Filter Trial Bag Test

KnowledgeBase: Strategies for Improvement

Our Capabilities: Analytical & Laboratory Services

Our Capabilities: Equipment Assessment & Inspections

Our Capabilities: Asset Planning