Improve Flow Distribution

Maintain Design Temperatures

The air heater is usually the last piece of equipment before a cold-side ESP. It transfers some heat from the flue gas back into the boiler system to pre-heat combustion air. This significantly reduces the temperature of flue gas heading downstream to the ESP, from about 700„‰ to about 300„‰.

Flue gas temperature is critical to ESP performance; both ash resistivity and gas volume increase with higher temperatures. The optimal operating temperature for a cold-side ESP is in the 280„‰-320„‰range. Temperatures above 350„‰ usually have a significantly negative impact on ESP performance.

At most plants, air heater exit temperature readings are readily available in the DCS.

If air heater temperatures are higher than normal, testing the combustion system is an effective way to determine why. High exit gas temperatures can be associated with excess air”indicating poor combustion control, which wastes energy and increases flue gas volume. Poor balance across the furnace is another likely cause. Mill performance, as well as ash chemistry, can alter particle size distribution, which can significantly impact ESP performance.

Combustion system testing to find the cause of high exit temperatures may be combined with checking the air heater itself to find out if flow quantities are optimal and/or if air in-leakage is a problem.

Minimize Air In-Leakage

Anything that increases the volume of gas being treated by the ESP is bad for collection efficiency. Finding air in-leakage can be complicated, since it can get into the system at many locations. If tramp air is suspected, the hunt for a source usually starts by observing oxygen (O2) meter readings.

At most plants, O2 meters are located at the economizer exit; readings from this location are used primarily for combustion control. Under normal conditions, the boiler exit meter will read around 3% oxygen. Some plants also have an O2 meter in the stack as part of a continuous emission monitoring system (CEMS). Normally, the stack meter reads a bit higher: between 5% and 6.5%. If the stack O2 meter reading is above 8%, air in-leakage may be a significant problem.

Regular testing for air in-leakage at multiple points should be part of every plant’s operating policy. Test results help direct repairs to duct-work and equipment, ensuring that whatever maintenance is done will have maximum impact.

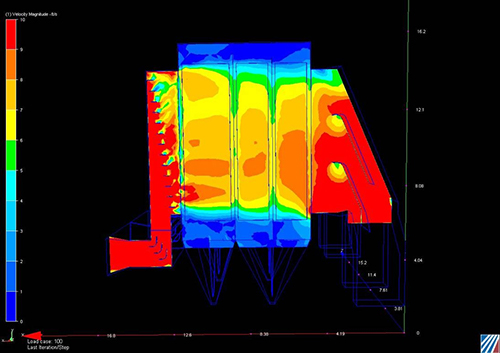

Optimize Flow Distribution Devices

The goal of the flow distribution devices in an ESP are to distribute the flue gases across the ESP as evenly as possible. When process changes or air in-leakage occur the flow profile of the flue gases change and the flow distribution devices may no longer be able to carry out this job efficiently. Another possibility is that the flow distribution devices get PM built up on them or deteriorate from corrosion. In any one of these situations the flow distribution is skewed and leads to poor ESP performance. In order to optimize flow it is important to check your devices and make sure they are clean and in good condition. If buildup is present, one option may be to add some type of rapping that will periodically clean these systems. If permanent changes to the process have changed, it may be a good idea to have a flow study done in order to find out how the new conditions affect the ESP and what can be done to correct this issue.

Helpful Resources:

KnowledgeBase: Optimize Corona Power

KnowledgeBase: Reduce ReEntrainment

KnowledgeBase: Theory of Operations

Our Capabilities: Gas Flow & Fluid Dynamics Modeling

Our Capabilities: Predictive Modeling