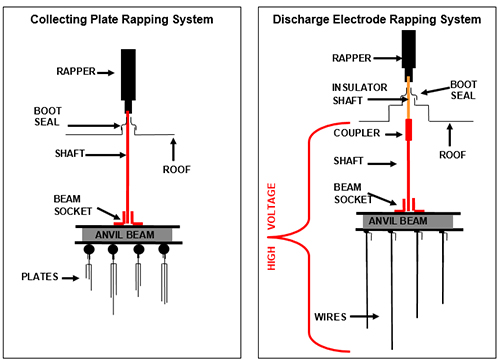

Major Components: Rapping Systems

Rappers are time-controlled systems provided for removing dust from the collecting plates and the discharge electrodes as well as for gas distribution devices (optional) and for hopper walls (optional). Rapping systems may be actuated by electrical or pneumatic power, or by mechanical means. Tumbling hammers may also be used to dislodge ash. Rapping methods include:

- Electric vibrators

- Electric solenoid piston drop rappers

- Pneumatic vibrating rappers

- Tumbling hammers

- Sonic horns (do not require transmission assemblies)

Discharge Electrode Rapping

In general, DE should be kept as free as possible of accumulated particulate. As a result, the rapping system for the discharge electrodes should be operated on a continuous schedule with repeat times in the 2 – 4 minute range, depending on the size and inlet particulate loading of the precipitator.

Collecting Plate Rapping

Collecting plate rapping must remove the bulk of the precipitated PM. The collecting plates are supported from anvil beams or directly with hooks from the precipitator casing. With anvil beam support, the impact of the rapping system is directed into the beams located at the leading and/or trailing edge of the collecting plates. For direct casing support, the impact is directed into the rapper beams located at or near the center of the top of the collecting plates.

The first electrical field generally collects about 60-80% of the inlet dust load. The first field plates should be rapped often enough so that their precipitated layer of particulate is about 3/8 – 1/2″ thick. There is no advantage in rapping more often since the precipitated dust has not yet agglomerated to form a sheet, which requires a minimum layer thickness. Sheet formation is essential to make the dust drop into the precipitator hopper without re-entrainment into the gas stream. Rapping less frequently typically results in a deterioration of the electrical power input by adding an additional resistance into the power circuit. Once an optimum rapping cycle has been found for the first electrical field (which may vary across the face of a large precipitator), the optimum rapping cycles for the downstream electrical fields can be established.

The collecting plate rapping system of the first field has a repeat time T equal to the time it takes to build a 3/8 – 1/2″layer on the collecting plates. The plates in the second field should have a repeat time of about 5T, and the plates in the third field should have a repeat time of 25T. Ideally, these repeat times yield a deposited layer of 3/8-1/2″ for the plates in all three fields. Adjustment may be required for factors such as dust resistivity, dust layer cohesiveness, gas temperature effects, electrical field height and length, and the collecting area served by one rapper.

Gas Distribution & Hopper Wall Rapping

The gas distribution plates used in an ESP should also be kept free of excessive particulate buildup and may require rapping on a continuous basis with a cycle time in the 10-20 minute range, depending on the inlet particulate loading of the precipitator and the nature of the PM. Gas distribution plates in the outlet of the precipitator may be rapped less often (every 30 – 60 minutes) due to the smaller concentration of PM that reach this area.

Helpful Resources

KnowledgeBase: Reduce ReEntrainment

KnowledgeBase: Improve Rapping Systems

KnowledgeBase: Equipment Improvements

Our Capabilities: Analytical & Lab Services

Our Capabilities: Equipment Assessments & Inspections

Our Capabilities: Precipitator Rapping Systems & Components